Our philosophy.

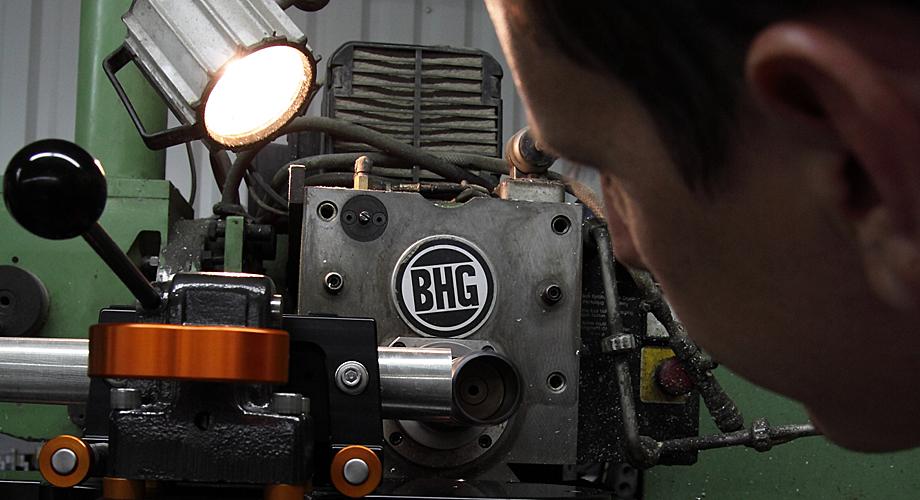

Our objective is to relocate bicycle production to France, and particularly to the Midi-Pyrénées region. The heart of our process is our own MILC Ind. frame production unit, supported by a carefully selected network of service providers, carefully monitored by MILC and capable of responding to all our requests. Independent of the nature of your project, and whether it is within the bike area or in another domain that would benefit from the same - very large – skill set used in bike production, we will cater to your needs.

WHY RELOCATE

In the mid-twentieth century, the bicycle industry was very powerful in France, Spain and Italy. In France it was largely concentrated around the city of Saint Etienne. The practice of cycling has never wavered; the sector remains strong despite successive crises and the development of various means of motorized transport. But the production of frames and components in France, as in the rest of Europe, has gradually declined and moved to Asia and particularly Taiwan for cost reasons.

The tide is turning…

Taiwan’s economic progress is mainly due to two industrial sectors: microprocessors and bicycling. Regarding the latter, the Taiwanese have over the years acquired expertise, particularly in the field of frame manufacturing. The resulting quality has triggered a move of the last industry players to Taiwan. However, production costs have seen significant increases over the years, tied to the increase in quality, but also the rise of living standards - and therefore wages - on the island. In addition, Taiwanese companies specialized in frame manufacturing have become huge and inflexible, a handicap especially when it comes to meeting the needs of medium-sized customers.

A shift is taking place, opening the way for the return of at least a portion of production in Europe, and this for pragmatic reasons:

1 . COST

The cost of local production in France is now quite competitive, and offers a light structure capable of responding to requests for production of small and medium size series. The gap has narrowed as regards pure production costs, and the transportation charges (freight, custom fees…) are increasing world-wide.

2 . INDUSTRIAL

Production in Asia suffers from a fatal Achilles heel: its lack of flexibility! Such flexibility is increasingly requested in bicycle industry for several reasons:

a. The large number of small and medium-sized brands, requiring manufacturing in small and medium size series, are facing providers developed build upon an economic model of mass production, which respond poorly to their expectations in terms of flexibility and time.

b. Increasing segmentation by major manufacturers, with a rising number of different models, made in much smaller series.

MILC is able to provide solutions of high quality offering unmatched flexibility; for example in prototyping, where manufacturing small and medium sized series are required.

3 . LOGISTICAL

It will always be easier, faster and less costly to transit goods within Europe, rather than having to use the route from Asia. Consequently our customers strengthen the efficiency of their logistics.

4 . ENVIRONMENTAL

The limited environmental impact of MILC Ind. is of course incomparable, even only taking into consideration the transport. In addition the fact that we accommodate raw material - tubes and machined parts - rather than full frames, reduces transport volume; and post-production shipping of bulky finished products takes place over shorter distances. And finally, MILC Ind. offers a range of services to complete a project involving various crafts that in our case are all offered locally, which significantly reduces the travel needs for engineers and production managers, as well as the transit of goods from one production point to another.

LOCAL PRODUCTION IS THE FUTURE

The approach of MILC Ind. is above all pragmatic and based on an analysis of the industrial and economic situation provided by experienced players in the bicycle industry.

We are convinced that the foundation of a strong economic model for the future is LOCALIZATION, not relocation. Relocation consists of bringing back production facilities to France and the rest of Europe, which had previously disappeared. But this should not be done based on wishful thinking, as noble as that is; instead it must be based on economic reality. That is how we see it.

Localization goes further. It is not opposed to globalization. On the contrary, it is the latest avatar. Globalization itself is neither good nor bad. It has been operated in a completely unregulated fashion, which has led to excesses. Today local production is the obvious choice for many economic actors, who are globalized but anxious to preserve the economic, social and environmental balances essential to their long-term survival.

In MILC Ind. we have been working with Asia for many years, and we continue to do so, especially in the field of material development. But our goal is clearly to localize production to France and other parts of Europe, if possible 100% of the production chain. We are not attempting to diminish the importance of Asia. Our view is towards a world where goods destined for the Pacific region are produced in Asia, whereas production of the same type of products for the European market is carried out locally. In other words we are looking to establish a system of SHORT DISTRIBUTION CYCLES, which make sense, economically, industrially and human-wise.