Welding.

Welding is the heart of our business. That is why MILC Ind. relies on its own welding unit, based in Ariège.

The level of perceived and real quality of welding in a bike is very high. If the appearance of the welding beads is the visible part of the iceberg, the submerged part often represents a particularly difficult technical challenge.

Accuracy is critical, with tight tolerance restrictions for the geometry of the frames. This requirement increased further following the development of mountain bikes with suspension and complex structures; combining shaped tubes with CNC parts, and composed of multiple pivot points which all need to be perfectly aligned.

The constant search for lower weight has also led bicycle manufacturers to develop materials in extremely thin layers, thus requiring extreme precision from the welders.

This level of requirement, unique to the bicycle industry, applies to all activities at MILC Ind.

PROCESS

MILC exclusively uses TIG welding, which is a process of arc welding with non-consumable electrodes. It is widely used for mass production in the cycle industry due to its adaptability and perceived high quality welding beads.

MILC masters TIG welding for any material, particularly for steel 4130 and aluminum 7005 and 7020, but also for stainless steel.

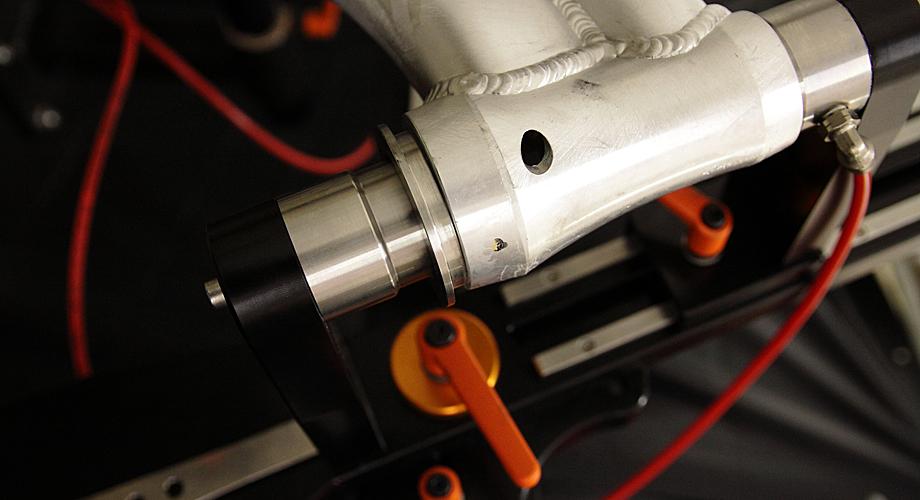

MILC uses an Anvil jig dedicated to the manufacture of bicycle frames, and fitted with a device enabling the provision of "reverse gas", which is especially useful for welding titanium or steels rich in molybdenum, which need the protection of a neutral gas (argon), in order not to oxidize when in contact with air, during the welding phase .

The expertise and skill of our welders allow the assembly of very thin layers, starting from 0.8 mm. Great care is given to the structural quality of the work but also to the aesthetical appearance of the beads, to which we pay special attention because of the generally high standard expected in this area.