industRY

tubular frames manufacture

Aluminium, steel, stainless steel, titanium… We work with every material used in the cycle and light mobility industry. We master tubular structures and associated skills, including cutting tubes, notching, and shaping steel, aluminium, stainless steel, and titanium tubes. We use the TIG and braze-welding processes to ensure extremely precise tube assembly.

401

back to top

401

back to top

tube work

bending

Bending is a key area of expertise in our mass and pre-series production daily. We do this in-house, particularly for prototyping. We outsource notching in France to partners chosen for their rigour and consistency.

notching

In-house, we notch the tubes of the future bicycle frame or mobility device. We only entrust tube laser cutting to our local partners. Notching is THE skill that enables us to build our chassis and ensure the perceived quality of our welded seams.

complex shaping

Complex shaping and hydroforming are rare skills, so we rely on our Asian partners, with whom we have been working for over ten years. We visit them regularly, at least twice a year.

extrusion and stretching

For both steel and aluminium, extrusion and drawing enable us to produce tubes with constant, customised cross-sections. In France or abroad, our partners enable us to obtain these shapes with affordable minimum quantities.

402

back to top

402

back to top

component work

foundry

We collaborate with a robust network of local and international partners. Our foundry expertise in all materials used in light rolling chassis enables us to offer solutions tailored to our customers’ needs

forge

When it comes to forging, we prioritise local suppliers and the sourcing of raw materials locally. When this is not possible, depending on our customers’ needs, we extend the circle of our suppliers as far as Asia. In particular, we have a very good knowledge of the Taiwanese industrial sector and regularly go there.

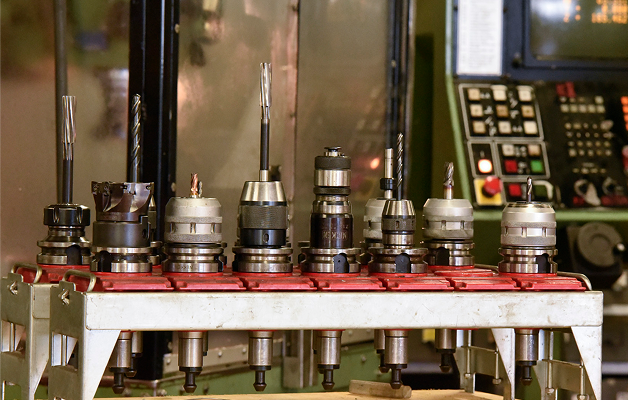

machining

When it comes to machining, we prioritise local suppliers and local sourcing of raw materials. When this is not possible, depending on our customers’ needs, we extend the circle of our suppliers as far as Asia. In particular, we have excellent knowledge of the Taiwanese industrial sector and regularly go there.

sheet metal work

Flatbed cutting and stacking have a strong local presence. Using fibre lasers, CO2 lasers and even water lasers, we rely on local experts to cut all materials.

injection

We work with a strong network of local and international partners. Our knowledge of injection enables us to offer solutions tailored to our customers’ needs.

403

back to top

403

back to top

welding

TIG welding

The perceived quality of welded seams is our obsession. From the very beginning, we have constantly sought to optimise our mastery of this fusion welding process. Today, we have achieved a high level of expertise in this field.

braze-welding

Silver or brass braze welding enables us to design precise connections that minimise distortion. Historically very present in the cycle industry, this traditional technique is one of our in-house skills.

robotisation CMT (Cold Metal Transfer)

Milc’s latest addition! Our CMT pulsed MIG robot increases output while maintaining the perceived high quality of weld beads. Robotic smooth welding is a goal @Milc.

404

back to top

404

back to top

bonding

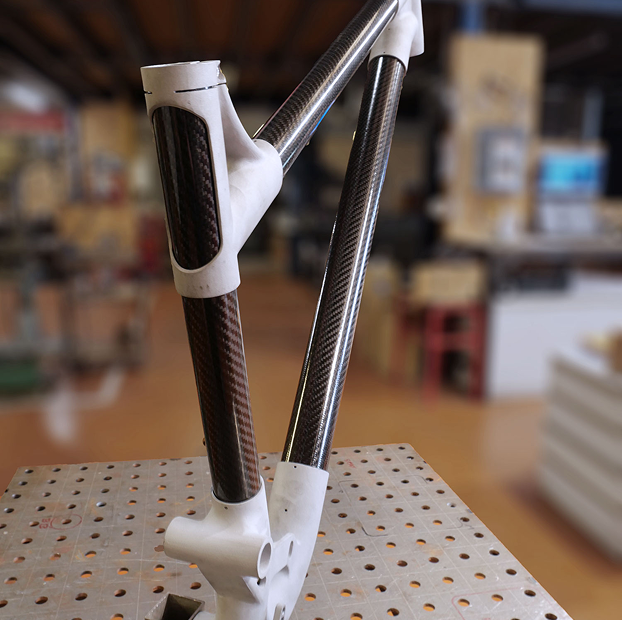

multi-material

Multi-material bonding reduces the cost of manufacturing mechanically-welded frames. We recommend it in particular for :

– rapid prototyping combined with 3D printing

– manufacturing accessories

405

back to top

405

back to top

surface finishing

frame finishing

The frame is the soul of the bicycle and of all micro-mobility devices. At Milc, we pay special attention to frame painting. For powder coating and liquid paint, we work with a network of subcontractors who are extremely meticulous in this area.

automated finishing

Milc industry’s key development area: optimising time-consuming process stages for component preparation. Before welding and surface treatment, automated finishing is one of the key ways of optimising the cost price of mechanically welded chassis.