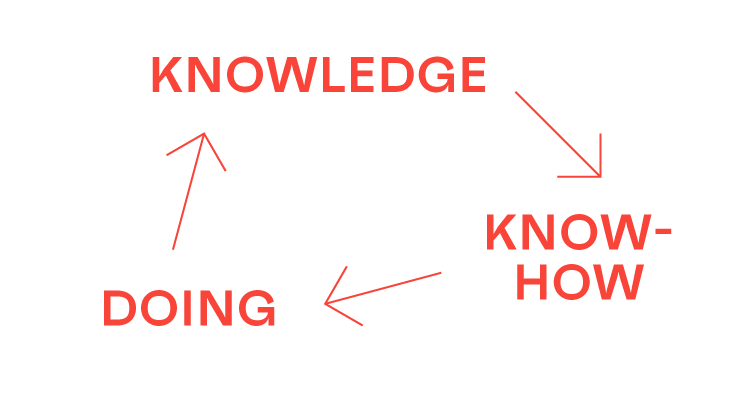

At Milc industry, we combine design activities (knowledge), prototyping (know-how) and mass production (doing). Our aim is to meet our customers’ needs across the entire value chain.

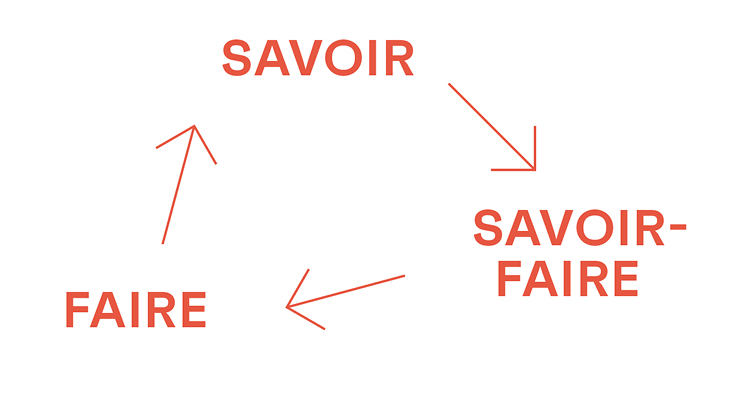

Chez MILC Ind., nous allions les activités de conception (le savoir), le prototypage et les petites séries (savoir-faire) et celles de fabrication (le faire) afin de vous accompagner de l’idée à la maturation complète du produit.

Since 2013, in France, near the Pyrenees, Milc Industry offers integrated solutions:

– frame manufacture,

– assembly,

– logistics

– mass production

– supply chain management

– prototyping and pilot run

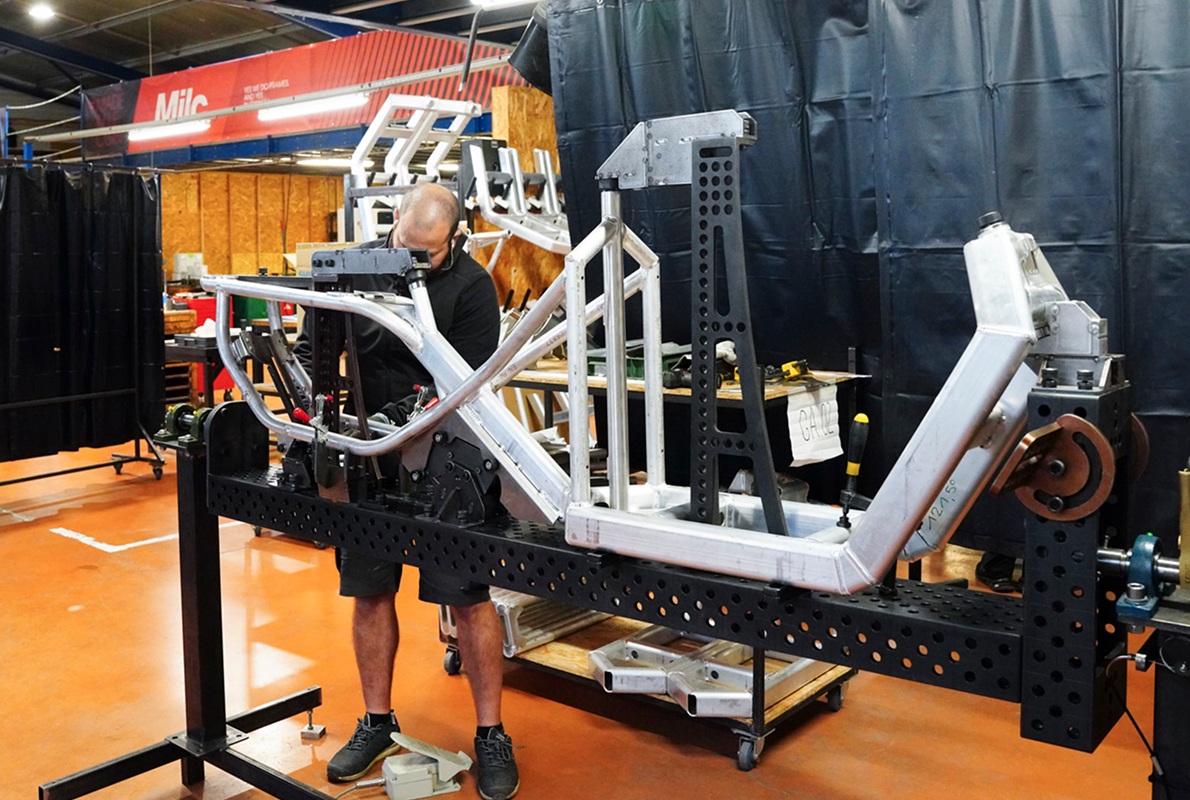

The frame, the soul of the bicycle

We come from the world of cycling — it is our natural market, our first target — even though our expertise extends well beyond this field. Nevertheless, our origins continue to shape us. We have acquired solid experience in the manufacturing processes involved in building a bicycle, but the core of our craft remains frame production — in other words, welding.

However, localising welding alone does not make sense if all other aspects of producing a finished product are not also handled locally. This is why, around our welding production unit, we have built a network of skilled trades capable of responding to every requirement — machining, forming, finishing, and more.

But why relocate production?

In the mid-twentieth century, the bicycle industry was strong in France, Spain, and Italy. Although cycling practices have evolved, interest in bicycles has never declined. The sector has remained resilient despite successive economic crises and the rise of motorised personal transportation.

However, frame and component production in Europe gradually diminished, shifting toward Asia, particularly Taiwan. The reason? Unbeatable production costs and the high level of expertise of companies established in the region, especially in frame manufacturing. Over time, however, both demand and production costs have increased significantly, limiting the ability of these companies to meet the needs of, among others, medium-sized clients.

This is where we are now witnessing the return of part of the production to Europe, and where Milc Industry comes into play, for four pragmatic reasons:

- economic: Production costs are now fully competitive for local manufacturing in France, thanks to a lean structure capable of handling small- and medium-scale production runs.

- industrial: MILC can deliver high-quality results while offering unmatched flexibility, both in prototyping and in small- to medium-batch manufacturing.

- logistical: It will always be simpler, faster, and more cost-effective to transport goods within Europe rather than shipping them from Asia.

- environmental: Upstream, transporting raw materials, such as tubes and machined components, instead of fully assembled frames, significantly reduces transport volumes. Downstream, the delivery of large finished products covers shorter distances, lowering the environmental impact.

More than just relocation

However, we strongly believe not only in the value of relocation, but in the broader concept of localisation as a forward-looking economic model. This concept goes even further. It is not in opposition to globalisation — on the contrary, it is its most recent evolution. Local production is now an obvious and strategic choice for many global economic players who seek to preserve the economic, social, and environmental balance essential to their long-term sustainability.

We have worked with Asia for many years and continue to do so, particularly in the field of materials development. Localising the production of consumer goods in Asia for the Pacific region, while producing the same goods locally for the European market, in other words, establishing short supply chains, makes complete sense from economic, industrial, and human perspectives.

Our background and the experience we have gained now allow us to shape our growth in full alignment with the needs expressed by our clients.

Whether it is an electric bicycle, a micro-mobility device, or any form of light mobility, your project can be fully supported by our teams. What are the advantages?

– reduced costs

– optimised project coordination

– greater responsiveness, thanks to the concentration of expertise locally and the overall management of the project by a single point of contact

And what about tomorrow?

We are scaling up our industrial capabilities with the construction of a next-generation factory. This site will be designed to minimise social and environmental impact, support sustainable mobility, and enable innovation in manufacturing processes, including the use of diverse materials, automation, and flexible, rapid production changeovers. This represents an investment of €4.5 million, with a gradual ramp-up aimed at reaching a production volume of 25,000 units by 2028.

The frame is the soul of the bicycle. Tube working and welding are at the heart of the cycle industry. Milc Industry is therefore structured around its frame manufacturing unit, based in the Hautes-Pyrénées region. We can weld to bicycle industry quality standards, meaning a very high level of precision, visual quality of the welds, tight tolerances in geometry, and excellent reliability.