industrY

assembly

At Milc industry, bicycles and micro-mobility vehicles are assembled by a team of specialist operators. Each technician has specific expertise:

– wheel assembly

– assembly of drive chains

– hydraulic assembly

601

back to top

601

back to top

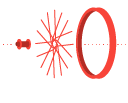

Wheel assembly

We assemble a series of spoked wheels and prototypes of electric bicycles and micro-mobility vehicles. Milc is equipped with a wheel assembly production line from Bikebotix #cocorico. We manufacture all wheel specifications, from children’s bikes to fatbikes, in all diameters and spoke sizes. We are also experts in:

- wheel reconditioning

- tyre assembly

- accessorising ready-to-ride wheels

We advise our customers on the technical choices to be made when assembling wheels: spoke diameter, number of crossings, etc.

Highlight: wheel reconditioning

Reconditioning at Milc means:

- a comprehensive service, from the collection of damaged wheels at your site to the delivery of fully reconditioned wheels

- in-depth product expertise, including inspection of hubs suitable for reconditioning and enhancement of technical performance

- a robotised wheel production line, made in France by Bikebotix

- a partnership with Mach1 – Bikebotix, with off-site component stock to optimise lead times

We work closely with your teams to understand the issues encountered with the wheels of your fleets in operation and recommend reconditioning solutions tailored to durability objectives and financial requirements.

602

back to top

602

back to top

Hydraulic assembly of suspensions and brakes

We bleed the brakes. We assemble the brake-fork-suspension trio. Milc’s added value: its high level of expertise in all these areas.

603

back to top

603

back to top

Electric vehicle assembly

We assemble 100% electric vehicles, 60% electrically assisted bicycles and 40% intermediate vehicles. We are equipped with a battery-motor controller.

604

back to top

604

back to top

Finished product assembly

Milc industry works on a white label basis for bicycle and light mobility manufacturers. Products assembled in our factory are delivered directly from our warehouses to end customers, be they private individuals, bike shops or distributors.

Our range of roadworthiness tests ensures the quality and recognition of finished products. We work on the issue of packaging with each customer. We can develop tailor-made packaging locally.