Development

prototyping

Before launching a mass-produced product, the prototyping phase is essential to guarantee the quality and reliability of the future bicycle or mobility device. The design of a prototype, its assembly and the debugging phase make it possible to validate the technical choices and prepare for controlled industrialisation, particularly with a view to local production.

201

back to top

201

back to top

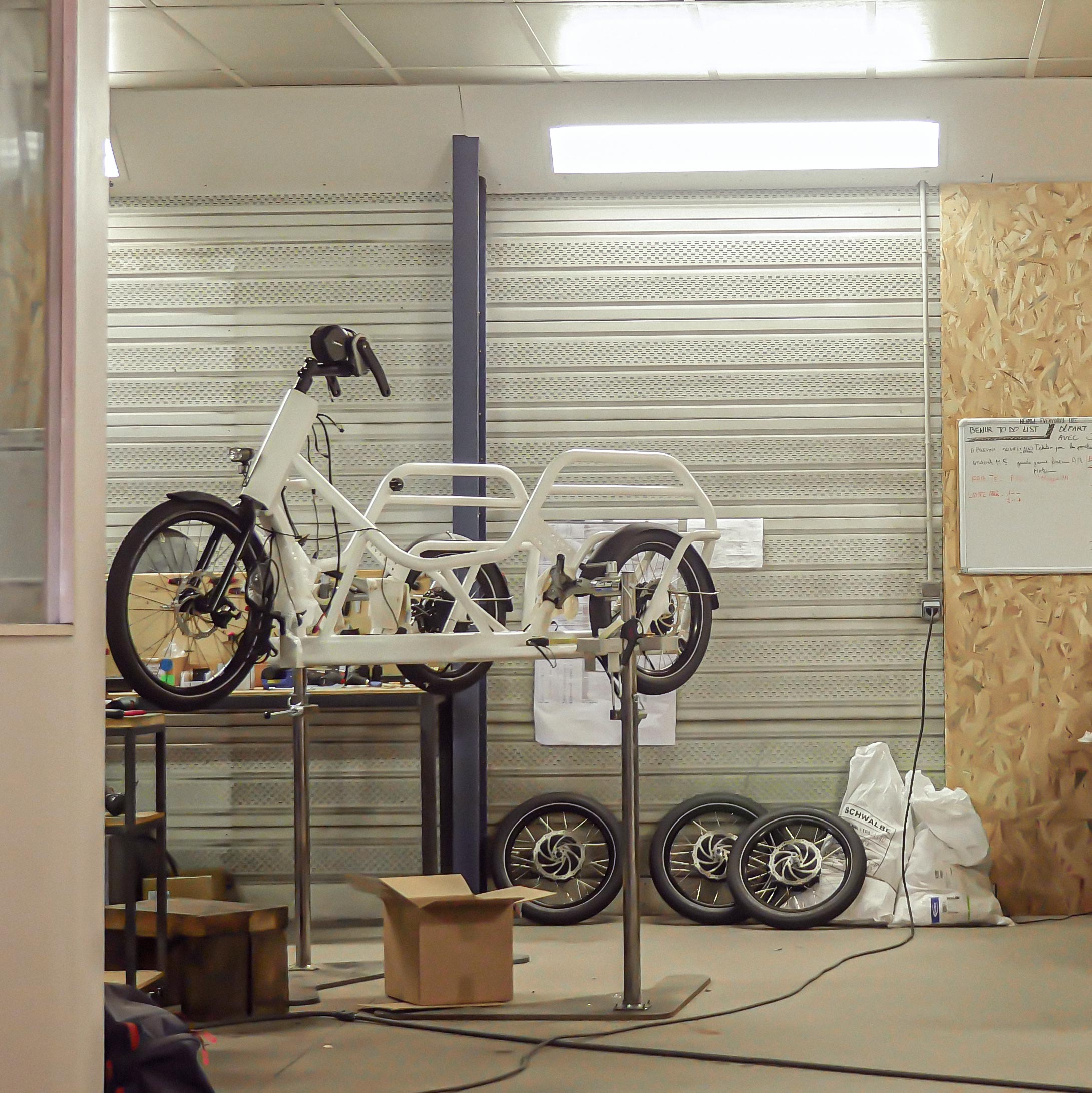

prototype manufacturing

The design of an electric-assisted bicycle prototype or a micro-mobility device enables us to test and validate the suitability of the product before it goes into pilot run or mass production. We check ergonomics, performance and ease of assembly. This precise, iterative work is essential for refining the design and guaranteeing industrial feasibility.

202

back to top

202

back to top

assembly and debugging

Assembling an electric bike prototype enables us to validate the industrial production process in real-life conditions. Debugging includes field tests to detect integration, adjustment or performance faults. This critical phase optimises the design and paves the way for a controlled transition to series production.

203

back to top

203

back to top

continual improvement process

h3

Body (…)

h3

Body (…)

h3

Body (…)